The Critical Link in Hazardous Area Safety: Ex Cable Glands

Choosing the right Ex gland is a decision that directly impacts the integrity and long-term safety of operations in hazardous locations. For facilities operating in ATEX or IECEx zones, selecting the appropriate gland for hazardous (Hazloc) areas is not optional; it is a mandatory compliance requirement that ensures the enclosure’s certified explosion protection method remains fully intact.

From the pressurized deep-sea rigs of the oil and gas sector to the solvent-rich environments of pharmaceutical mixing plants, Ex cable glands are the essential safety link for electrical systems across all hazardous industrial applications.

Rated cUS Class 1, Div 2, Ex cable glands are designed for use in environments with potential fire or explosion risks. Rigorous safety approvals let customers, installers, and regulators know the product has been tested against key national standards. This testing is done to prevent serious risks like fire and electric shock.

4 Critical Benefits of Ex Cable Glands

Industries dealing with flammable substances or combustible dusts in hazardous zones benefit from these operational and compliance aspects of plastic, brass, and stainless-steel Ex glands:

- Safety and risk reduction: The most important benefit, Ex glands offer an engineered barrier to prevent electrical faults (such as arcs or sparks) within an enclosure from igniting.

- Regulatory compliance: Using Ex glands is mandatory for maintaining the compliance and certification of the entire electrical installation in hazardous zones.

- Equipment integrity: By providing robust mechanical retention and high Ingress Protection (IP) ratings (e.g., IP66/IP68), these glands seal the electrical enclosure against damaging elements like moisture, dust and corrosive chemicals. They also prolong equipment life.

- Reliable earthing/grounding: For armored cables, the glands ensure a safe and reliable path for fault currents via the armor, which is crucial for overall system grounding and preventing static buildup.

Sealcon’s Ex Line of Cable Glands — and the Exceptional A2F

Our Ex glands offer protection types:

- Ex-e (Increased Safety): Prevents sparks or arcs.

- Ex-d (Flameproof): Withstands internal explosion pressure.

You can choose from Metric, PG or NPT threads with options for flat cable inserts, multi-hole inserts, and EMI / RFI protection.

A space- and cost-saving option is the A2F cable gland, the core of which is the EXIOS Hazloc rating. This isn’t just a compliance stamp; it signifies that the A2F is engineered beyond typical specifications, offering superior protection in areas where safety is paramount.

Cable glands often fail due to extreme thermal stress. But the A2F gland (Class 1, Div 2, cUS ATEX, IECEx) has been thoroughly tested, and passes the latest thermal conditioning tests. This means it can reliably withstand the severe, fluctuating temperatures that are a common operational challenge in harsh environments.

High-Performance EXIOS Features

EXIOS armored and non-armored glands meet stringent international standards and offer an extra-tight seal with high pressure ratings, often meeting IP68/IP69K (submersible and high-pressure washdown) and NEMA 4X & 6 ratings.

What’s more, many styles feature a dual seal on both the inner and outer jacket of the cable, boosting integrity and strength.

Ready for a custom quote? Contact Sealcon for more information about Ex cable glands or browse our Ex line.

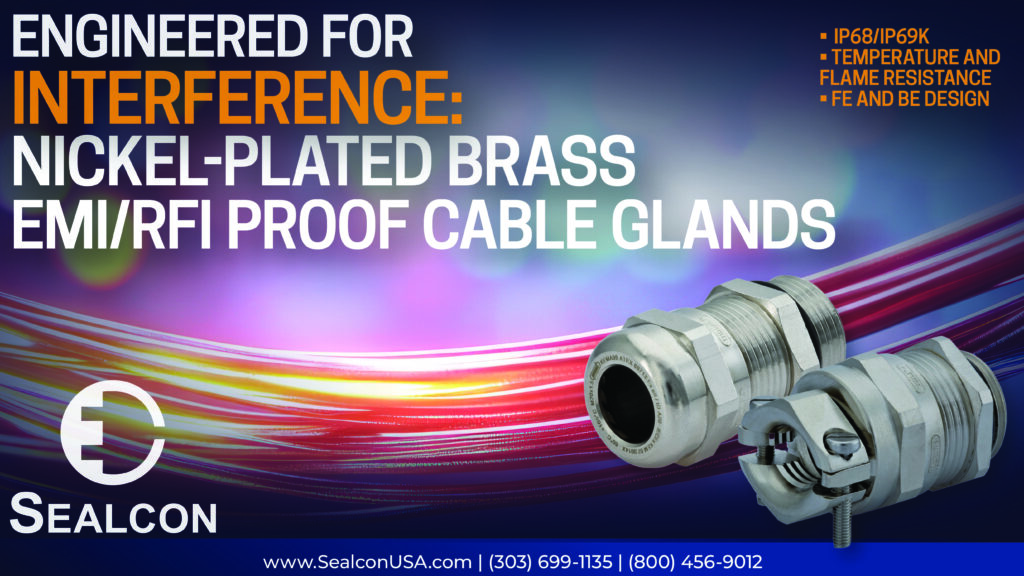

Engineered for Interference: Nickel-Plated Brass EMI/RFI Proof Cable Glands

Engineered for Interference: Nickel-Plated Brass EMI/RFI Proof Cable Glands  Stop Wire-Guessing: Find Your Perfect Cable

Stop Wire-Guessing: Find Your Perfect Cable  Final Push: Time to Buy Your Cable Gland Solutions Before 2026!

Final Push: Time to Buy Your Cable Gland Solutions Before 2026!