Why Sealcon Should Be Your Brand of Choice in Cable Management Because Peace of Mind Beats an Overstuffed Catalog In the fast-paced world of industrial automation, robotics, and food processing, reliable cable management isn’t just a detail—it’s mission-critical. Whether you’re wiring a control panel, designing a conveyor system, or managing connections in a data center, … Continued

Food Processing, Conveyors, and Frozen Pizza: The Role of Sealcon Products The frozen pizza industry is a significant sector in food processing, requiring efficiency, precision, and durability at every stage of production. From the mixing of dough to the final packaging, conveyors are a crucial part of the production process, ensuring that ingredients move smoothly … Continued

In the rapidly evolving landscape of medical technology, the spotlight often shines on groundbreaking devices and diagnostic tools. Yet behind every innovation lies a critical layer of infrastructure components that ensure safety, reliability, and compliance. Among these, cable glands, circular connectors, enclosures, and conduit systems play an essential role. And with some of the highest … Continued

Pick & Place Robotics Need High Quality Cable Management Solutions from Sealcon Modern robotics has come a long way from its humble beginnings, when early robots were assembled from old war surplus parts and alarm clocks. One of the earliest examples, the “tortoises” Elmer and Elsie, were built by W. Grey Walter. These robots were … Continued

Wouldn’t it be amazing if we could reduce traffic, shorten commutes, and make our cities safer? What if you didn’t need to know every back road in town because the technology could guide you in real time? With emerging innovations, this dream is becoming a reality. But how is that possible? The Power of 5G … Continued

With the rapid growth of data centers and their increasing energy demands, every detail must align to ensure future reliability and operational efficiency. These intricate systems must handle massive data flows while meeting the insatiable thirst for power and energy requirements of modern technology. Essential Cable Management for Modern Data Centers from Sealcon To meet … Continued

We all love convenience—whether it’s ordering a combo meal or receiving packages from online shopping. Imagine if your Cable Management Solutions Supplier could offer that same level of ease and efficiency. Sealcon’s Value-Added Pre-Packaging delivers exactly that. Our innovative custom kitting solution bundles Cable Glands, Locking Nuts, and O-Rings into one pre-packaged bag. This approach … Continued

At Sealcon, we’re proud to serve the diverse needs of customers across the United States, Mexico, and Canada. With our recent website upgrade, we’ve expanded our language capabilities to better support our growing community across North America and beyond. Now, with content available in English, Spanish, French, German, Chinese, Hebrew, Hindi, Malay, Portuguese, and Vietnamese, … Continued

As we approach the end of 2024 and prepare for 2025, demand for Ex-e and Ex-d cable glands, M23 connectors, and PVDF solutions has surged. To ensure we can fulfill your orders before the end of the year, we urge you to act now. We value your business and want to make sure you receive … Continued

In the world of manufacturing and heavy industry, reliability and efficiency are paramount. Paper mills, recycling facilities, chemical plants, and pharmaceutical waste operations all require advanced equipment to ensure safe, continuous operations. For environments that demand robust and versatile solutions, Sealcon’s A2F Cable Gland is the cost-effective, space-saving answer. Cost-Saving, Space-Saving Design of the Sealcon … Continued

With the introduction of computers in the 1960s, the development of Computer Numerical Control (CNC) machines revolutionized manufacturing. Previously, highly skilled operators handled tasks that were limited in scope and repeatability. John T. Parson is credited as the father of CNC machinery for his collaboration with MIT (Massachusetts Institute of Technology). Over the decades, CNC … Continued

In Jules Verne’s Twenty Thousand Leagues Under the Sea, published in 1870, we are introduced to the submarine Nautilus. This vessel, with its sophisticated systems and capabilities, allowed Captain Nemo to uncover the great mysteries of the deep sea. What was once science fiction is now becoming reality with the advent of new AUVs (Autonomous … Continued

Concerts today are not only about the music, but a convergence of light and sound that culminates in a next level show experience. For excited fans anticipating the performance of their favorite artist, this can be the event of a lifetime. Now, imagine the lights or sound systems fail. Thousands of invested fans who have … Continued

Cable glands play a key role in providing seamless connections in a diverse range of industries, including automotive, aerospace, manufacturing, medical, and more. Cable glands Connectors must deliver dependable performance in the varying environments involved with these applications, so customization of construction and materials is often necessary. One way cable glands connectors are specialized for … Continued

According to recent agricultural production statistics, in the past two decades, the world has seen a steady upward trend in world agricultural production to meet expanding demand, with the production of primary crops growing by 54 percent between 2000 and 2021. This expanding demand has the farming industry looking for ways to profitably keep up. … Continued

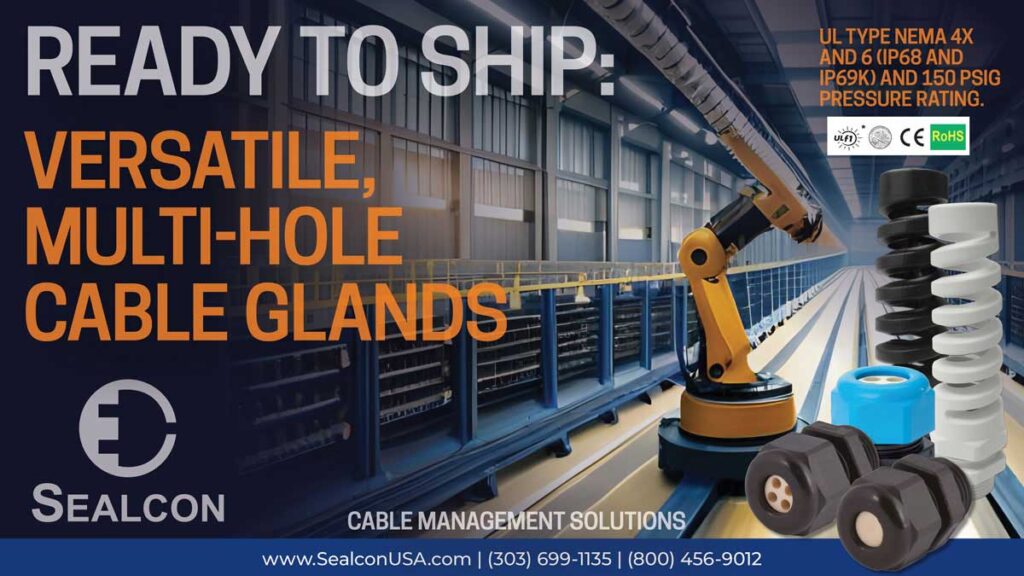

Sealcon is pleased to report that our elastomer based cable glands are once again available to meet a wide range of application needs. After resolving supply chain issues with elastomer availability, we are able to resume shipment of these popular cable glands that are developed to provide versatility and the utmost sealing protection. Nylon … Continued

image via vecteezy.com Sealcon Exclusive: The Game-Changing Power of DIV Rated – Fiber-Reinforced Cable Glands Imagine a bustling oil refinery, where flammable vapors linger in the air and the slightest spark could trigger disaster. In these unforgiving conditions, reliable cable protection is essential. That’s where Sealcon’s fiber-reinforced nylon cable glands offer protection beyond metal. Chemical … Continued

Image via vecteezy.com As 2023 comes to a close, it is time to start thinking about 2024! The industrial and electrical market is recovering and growing quickly and having the correct product on time is crucial. We are seeing 2024 as having great potential with growth in areas such as lighting, alternative energy, transportation, automation … Continued

image via vecteezy.com Cable glands play a vital role in securing cables and wires and protecting your application from failure due to environmental factors and damage. Without the correct quality cable management solution, you are risking potential failure of your application, damage to components, and possibly many headaches. Different applications require different types of cable … Continued

image by Vecteezy.com In recent years, the electric vehicle (EV) movement has ramped up, leading to a significant increase in the adoption of electric buses, commercial vehicles, and fleet vehicles. At the same time, fleet managers are integrating Internet of Things (IoT) technologies into their operations to optimize the management of buses and commercial vehicles. … Continued

image via Vecteezy.com Wow time flies when you are having fun! 2023 is getting closer to wrapping up and now is the time to start placing your orders for the end of the year. Even though Sealcon has an extensive supply of cable glands, circular connectors and many other cable management products stocked in our … Continued

image via vecteezy.com Much of industry is now driven by technology. The Industrial Internet of Things (IIoT) is revolutionizing the way industries use these digital systems to increase efficiency, reduce costs, and drive innovation. IIoT systems represent the means by which these technologies are tied together, providing rapid communication and data transfer. The IIoT ecosystem … Continued

photo by Benis Arapovic at Vecteezy As digital technology and industrial automation become more integrated into manufacturing processes, dependable panel and control modules are essential for ensuring seamless operations across multiple sectors. From power distribution to process control, these interfaces serve as the nerve center of operations. Reliable cable glands are crucial for panel and … Continued

Image by stockgiu via Vecteezy The food processing industry has embraced automation, and indications are that its adoption in the food and beverage industry is expanding rapidly. According to a robotics report by the International Federation of Robotics (IFR), in 2021, “the food and beverage industry installed 25% more robots, reaching a new peak level.” … Continued

Photo by Khwanchai Phanthong at Vecteezy In today’s age of automation, a reliable connection is required for the transmission of data, power, and signal to complete an operation or function. In the past, a mechanical device may have only operated by an on/off function by the use of a power cord, but with technological advances, … Continued

Photo by lucy3chihuahua212291 at Vecteezy Governments around the world are strongly encouraging the adoption of electric vehicles (EVs) through incentives like tax credits, rebates, and grants. Governmental pressure through legislation is growing for the implementation of EV technology, not only in the private sector, but for a wide range of government fleet vehicles. The goal … Continued

In our highly electronic and digitized world, cords, wires, and cables of all sizes and capacities are ubiquitous. Dependable cable management performance is essential for cords and cables to provide power transmission, data transfer, networking, and more without damage. Since they are used in a diverse range of environments, cable glands with unique characteristics are … Continued

Sealcon makes it easy to find the right component for your OEM application. Product quality,unsurpassed customer service, and product availability set Sealcon apart from the competition. Photo Credit: Ave Calvar from Unsplash The increasing need for connectivity in an ever-widening sphere of products and processes have made dependable connectors and cable management components for OEM … Continued

Sealcon offers an extensive line of products for utility industry applications, with unique characteristics suited for the specific job environment. — Image by tawatchai07 on Freepik Utilities are a vital part of the nation’s infrastructure. A wide variety of equipment and devices are essential to the proper and consistent functioning of our national and local … Continued

A 2022 survey conducted by Deloitte and FMI-The Food Industry Association (FMI), reveals that digital skills are in demand for food industry positions. It also suggests a trend toward increased use of digital technology in the food processing industry. In addition to food retailers embracing more digital operations, there is a rising need for technology … Continued

World governments have become increasingly focused on the removal of CO2 from the atmosphere to stop global warming. Efforts to end the threat of excessive greenhouse gases, namely CO2, center on reaching “net zero” goals, which means the amount of greenhouse gas emissions going into the atmosphere are balanced through removals. The transition from fossil … Continued

photo credit Ricardo Gomez Angel via Unsplash Mining continues to be an essential industry across the globe. From the need for rare earth minerals used in the development of electric vehicles, to the coal needed for electrical plants to meet increasing demand, mining operations are an important industry. While the market remains strong, the mining … Continued

Image of robotic automation of factory producing cars. Sealcon has connectors for robotic applications. A wide range of businesses have integrated robotics into their operations, realizing benefits such as increased efficiency, improved safety, higher productivity, and enhanced quality control. Robotic automation has brought benefits to processes such as assembly, packaging, quality inspection, and more. During … Continued

Food safety is always a concern for manufacturers and processors of food related items. Even though in the United States sickness from food borne illnesses is at an all time low, manufacturers are always striving to keep their customers healthy and provide quality products. This does not only mean they are concerned with just … Continued

In the early 1900’s, the assembly line concept revolutionized manufacturing and made the automobile affordable for working class households throughout the United States. Since that time, automation and robotics have further enhanced assembly line capabilities, increasing productivity and profitability in a wide range of industries. As manufacturing has become more specialized and diversified, assembly lines … Continued

Sealcon is the go-to source for connectivity needs in the automated car wash industry. Our comprehensive line of cable glands and connectors include options that are specifically designed to withstand and work dependably in the harsh, demanding conditions in automated car washes. Why Sealcon Products are Ideal for Automated Car Washes Sealcon connectors have an … Continued

Throughout the 20th century, a host of electric lighting technology developments occurred, leading to a diverse range of lighting applications that we use in virtually every aspect of life. From homes and businesses, to institutions and industries, electric lighting has enhanced society’s quality of life and productivity. As a new era of lighting innovation continues … Continued

From lighting accessories and controls to GPS systems, today’s recreational and luxury boats are equipped with a wide range of high tech accessories that require dependable connectivity. Like the components used in the manufacture of mechanical watercraft assemblies, marine accessories must have the ability to withstand not only continual exposure to water but harsh outdoor … Continued

Over the past few years, several governments and car manufacturers have set goals to phase out sales of internal combustion engine cars within the next two decades. Concurrently, the EV market is quickly growing to overtake traditional automobiles as the new preferred vehicle technology. As discussed in a report from the International Energy Agency (IEA), … Continued

Sealcon cable glands use inserts to achieve the level of approvals required for application and industries. We have many to choose from including Buna-N, FKM, Silicone (red) and Silicone (Blue – FDA compliant). Each has a specific protection that it is produced for. What is Buna-N? Buna-N or Nitrile rubber is a synthetically produced, petroleum-based … Continued

Sealcon’s A2F cable gland features an innovative design that saves space with its smaller footprint along with the weight and cost savings that go with that. It is available in Metric or NPT threads and comes with an O-Ring on Metric thread Options. The O-Ring groove protects the O-Ring seal from damage. The A2F cable … Continued

The complex global supply chain has a an ever-stronger demand for customization along with the desire for more data collection. Manufacturers and OEM’s are attempting to gain productivity improvements and uncover new ways of streamlining manufacturing and supply chain production. Sealcon can help with its vast portfolio of products. Among them is our Hybrid connectors … Continued

The low profile of the VariaPro cable gland makes it ideal for smaller spaces. The VariaPro line of Cable Glands is made for enduring extremes. It could be hot, cold, or acid the VariaPro line is ready. These are the cable glands for particularly extreme requirements. Each of the three varieties of the Varia Line: … Continued

A Miniaturization Powerhouse We used to hear the business buzz about “Bigger is Better”. Well, not when it comes to manufacturing. In manufacturing it is about the ever-smaller mechanical, electronic products and devices. Yet the power needs are just the same or more. Look no further than the Sealcon M12 Power Circular Connector. This compact … Continued

The Sealcon Twilock-S connection system is an extremely simple and highly reliable quick fastening system. Our Twilock-S metric circular plug-in connectors mate to Speedtec by Intercontec/TE Connectivity making adaptivity between these two connector systems technically possible. All it takes is just one click, a slight twist and the plug-in system goes from “Open” to “Close”; … Continued

Sealcon has expanded our industrial enclosure products with the addition of our Premium Series P, Impact Series I and Genesis Series G lines. These premium polycarbonate enclosures are lightweight, impact, high temperature, UV and fade resistant. These are in addition to the fiberglass industrial enclosure line we have in: Select Series S, Origin Series O, … Continued

Covid Brings New Challenges to Boating Industry COVID travel and gathering restrictions has led to an increase in outdoor activities such as recreational boating. According to data reported by Barrons, “total new U.S. recreational boat sales in May were the highest in a single month since 2007, with increases across all segments.” With the effects … Continued

Enclosures are integral in protecting vital components from the elements. To assure the best industrial enclosure selection there are questions to consider.

The seismic shift the coronavirus pandemic has had on day-to-day life is unprecedented. It’s hard to believe how a microscopic agent has the power to disrupt the market, the economy and supply/demand chains on a global scale—but it has. The 1918 Spanish flu pandemic is the only one of comparable scale. However, a big difference … Continued

Sealcon Announcement Regarding COVID-19 As a supplier to critical manufacturing sectors in the area of medical equipment (ventilators, hospital beds, x-ray machines, scales, etc.) as well as utility (communication) and safety equipment (fire and rescue), Sealcon has been deemed essential and is exempt from any federal and state mandated stay-at-home orders. In that spirit, Sealcon … Continued

Sealcon is facing a global market demand for one product covering both, ATEX / IECEx, and UL class/zone approvals. With Sealcon’s new BXA Active series user has the opportunity to drastically reduce its supply chain and engineering efforts by meeting UL Class/div and the ATEX requirements with only one single solution. Along with the existing ATEX / IECEx approval the BXA Active series is now certified cCSAus for Class / Zone which allows using the Glands also in Class I and II Division 2 applications after NEC codes 501 and 502.

As a supplier to Critical Manufacturing Sectors in the area of Medical Equipment (Ventilator, Hospital beds, Scales and X-Ray machine, etc.), as well as Utility (Communication) and Safety Equipment (Fire and Rescue Equipment) we have been asked to remain open. We therefore asked our employee to come to work as well. We’ll continue to adhere … Continued

Enclosures for High-Density Cable Management Needs If engineers were allowed, they would give you 50 buttons—but when you’re driving it’s not feasible to use them all, so it’s better to have the select few that you really need. Sealcon LLC prides itself on offering selective and personalized product solutions for specific application requirements. In … Continued

We are proud to announce that we are expanding to cover the entire country of Mexico. Now we can offer the same great products and customer service that we have been known for in the United States and Canada. In addition to a technical support staff in the United States, we also have local representation … Continued

Sealcon is excited to announce our new line of UL approved enclosures. All of our enclosures are made of either polycarbonate or polyester, making the enclosures extremely durable and resistant to both heat and chemicals. All of our enclosures are UL rated and come in variety of sizes and styles. To learn more about our enclosures, … Continued

We offer all components of cable management solutions. In addition to cable glands, enclosures, and conduit, we also offer hundreds of accessories to complete any project. One our most popular accessories are our thread adapters available in either nylon or nickel plated brass. If you have components that don’t match up due to having different … Continued

With the development of technology improving every day you want to ensure that data is being collected and transmitted quickly and reliably. Our M12 signal cordsets offer unparalleled connectivity along with the advantage of data and communication flow in a wide array of industrial applications. They are well-suited for applications in which a compact, dependable … Continued

In dynamic applications, you want components that are both durable and don’t take up a lot of space. This is especially true for industries such as robotics, railways, and automation. For these applications we recommend using our PoE M23 circular connectors. These hybrid connectors offer Ethernet transmission up to a one gigabyte range (Cat7) as … Continued

Come See Us At IMTS 2018! Sealcon is proud to be showcasing our products at the IMTS convention this year. With over 2,000 exhibiting companies, IMTS is America’s largest premier manufacturing show. We will be showcasing our M8-M40 circular connector collection as well as our extensive selection of strain relief fittings. If you are … Continued

Dynamic applications require components that allow for free movement. Standard dome cable glands are great for securely holding wires in place, but if they are used in a non-static application they could cause kinking and chaffing to occur and cause damage to the wire. To protect your wires and minimize repairs in industries such as … Continued

Circular connectors have become the “go to” solution for automation systems because of their benefits over hardwired systems. Circular connectors are easy to use, compact in size, extremely adaptable, and rugged enough for outdoor use. One of the most popular circular connectors that we have to offer is our robust M23 connectors. Our M23s are … Continued

Solar and other alternative energies are efficient, reliable, and have been adopted around the world as a source of clean and affordable energy. In such a large and expanding industry, you want to make sure that every piece of equipment can withstand the harsh conditions of the outdoors. Sealcon offers a variety of products that … Continued

In the food and beverage industries you want to make sure that your products avoid contamination at all costs. Microorganisms and dirty equipment can lead to unwanted impurities which can harm the health of your consumers and your business. Sealcon offers a large number of products that meet the hygienic requirements of the food and … Continued

The M23 TWILOCK – S is the most versatile circular connector that we have to offer. It has the same functions as our normal M23 connector with it our TWILOCK – S quick connect locking system. This connector is much faster to install than the standard M23 screw connection, a ¼ twist is all that … Continued

Sealcon’s M23 circular connectors are the robust connectors that you’ve been searching for. The M23s are available with either power or signal inserts and are compact enough to fit into nearly any environment. Our M23s are built to the highest standards, earning them a pressure rating of IP 67 / IP 69. The durability of … Continued

You may have seen some of our other products and thought, “Those are great and all, but in my line of work there is a significant risk of fire and explosions. What about me? What about my needs?” We have you covered with our EX line of products that are designed to withstand hazardous applications … Continued

Sealcon has two different options for the cable material for both our M8 and M12 cordsets. The standard material of our wire coating is a PVC coating. The PVC coating is a more cost effective solution which is ideal for operations requiring less movement and bending of the cable. In addition to the PVC coating … Continued

Sealcon’s RG and FP Hygienic Cable Glands are ideal for any application where cleanliness is a priority. The smooth stainless steel shell is specifically shaped to stop the settlement of microorganisms and debris by removing the nooks and crannies where they typically thrive. The liquid-tight design coupled with the stainless steel make these glands extremely … Continued

Our new M23 TWILOCK-S connector comes in a newly redesigned right-angle panel mount. The right angle panel mount, like our other M23 TWILOCK –S connectors, can be equipped with either a power or signal insert and is intermateable with Speedtec® by Intercontec/Tyco. The panel mount has been recently redesigned to make it more robust and … Continued

Over a century ago, the industrial revolution marked the development of a new age of machinery and equipment, laying the foundation of an era of unprecedented productivity. In recent years, a similar revolution has emerged in the form of internet-driven communication capabilities. Today, the merger of industrial processes and internet connectivity has created a new … Continued

RJ45 Strain Relief Protection without the hassle Our RJ45 strain relief connector is the solution for securing Ethernet cables. The insert has a slit that wraps around the cable, allowing the cable to be held tightly while saving you the hassle of cutting and reterminating the wire. The RJ45 strain relief is available in nickel … Continued

Sealcon’s new M23 Power & Signal Twilock-S Connectors is intermateable with Intercontec/Tyco’s Speedtec® technology. We offer 3 shell types in Signal and 2 shell types in Power with all common pin-out configurations. The reliable 1/4 turn quick-connect technology is the only brand crossing to Speedtec. Contact us today for more information!

Sealcon has developed several conduit lines to provide reliable protection that offers a versatile protection range to all types of cable. Hot and cold temperatures, tensile and compressive loads and wear-and-tear can cause severe damage to cables resulting in malfunctions and loss of production. Prevent your wires and cables from damage with our wide range … Continued

Jaeger Connectors by Sealcon offers adapted connectors to be used in rough industrial environments. With an extensive product line ranging from Standard & Rapid to Robotics and Power Series, a solution is available for your every need. These connectors are continuously adapting to meet the needs and remain at the forefront of many industries including … Continued

The Hygienic Cable Gland design from Sealcon has been developed for applications where food safety and cleanliness are of the highest importance. Sealcon features two specially designed hygienic glands to outperform the extreme demands of the market. Both the FP and RG Hygienic Gland feature a smooth design which nearly eliminates any crevice that could … Continued

Sealcon’s M12 Cordsets are ideal for the Automation and Manufacturing industries! Automation in manufacturing is increasing at the speed of technology, with IIoT and smart machines; a durable and reliable connectivity solution is required to maximize output. Sealcon now has M12 connector cordsets that are ideal for your application and will meet and exceed the … Continued

Is your thread size off by one size? We have the solution for switching thread types and sizes! We carry a wide variety of locking nuts, thread adapters, reducers, enlargers and accessories. Are you are dealing with foreign products or non-matching thread types? Our adapters will eliminate that problem by converting holes which fit PG, … Continued

In industry, cables and wires are exposed to exceptional loads. Heat and cold, tensile and compressive loads and wear-and-tear, all of which cause damage to cables and can result in malfunctions and loss of production. Prevent your wires and cables from damage with our range of conduit protection. The Poleon Plastic range and the galvanized … Continued

We Have Hygienic Glands for Food Processing! The Hygienic Cable Gland design from Sealcon has been developed for applications where food safety and cleanliness are of the highest importance. Sealcon features two specially designed hygienic glands to outperform the extreme demands of the market. Both the FP and RG Hygienic Gland feature a smooth design … Continued

Jaeger Connecteurs by Sealcon offers adapted connectors to be used in rough industrial environments. With an extensive product line ranging from Standard & Rapid to Robotics and Power Series, a solution is available for your every need. Jaeger is continuously adapting to meet the needs of many industries including automation, robotics, power, medical, automotive, marine, … Continued

The new compact & powerful M12 Power Circular Connector opens the door to entirely new applications and capabilities! The M12 Power Circular Connector boasts a high power transmission, a compact design, large temperature range and convincing electro-mechanical features. This is a major milestone in an age of miniaturization! The benefits of the M12 Power Circular … Continued

The new compact & powerful M12 Power Circular Connector opens the door to entirely new applications and capabilities! The M12 Power Circular Connector boasts a high power transmission, a compact design, large temperature range and convincing electro-mechanical features. This is a major milestone in an age of miniaturization! The benefits of the M12 Power Circular … Continued

Sealcon is proud to announce that our new Hygienic RG gland has been UL and UR approved! The high pressure spray down capabilities of this cable gland make it the perfect solution for many industries. From food processing, bottling, Medical, Pharma and many other applications, this is the perfect solution! With a smooth surface that … Continued

With food safety and cleanliness being a priority in food processing and bottling, Sealcon now has 2 specially designed hygienic glands to outperform the extreme demands of the market. The FP gland is perfectly designed for foam cleaning applications and our RG gland is perfect for applications where high pressure cleaning is needed. Both glands … Continued

With our wide variety of nylon and metal conduit, we have the solution for your application! Whether you are looking for a product that requires flexibility or one that requires extreme temperatures, we have you covered. Contact us to today and one of our trained technical representatives will be more than happy to help you … Continued

Cables and wires are exposed to exceptional loads. Hot and Cold cause damage to cables resulting in malfunctions and loss of production. The HUMMEL Meleon and Meleon Pro B cable protection conduits provide reliable protection that can withstand extreme changes in temperature. Meleon is a cable conduit made of galvanized steel (Meleon A) and is … Continued

Introducing the new Poleon and Meleon Conduit! Conduits provide reliable protection with versatile protection range. The Poleon plastic range and the galvanized steel protective tubing of the Meleon range offer suitable solutions for every application. A wide range of fittings makes it easy to find the right answer for every requirement! Nylon Conduit – Poleon … Continued

The Hygienic Cable Gland design from Sealcon has been developed for applications with special requirements demanding quality and performance. They are used in areas where highly hygienic standards for cleaning are required, specifically areas where deposits of bacteria and microorganisms need to be avoided. o The elastic membrane sealing avoids cable slipping o Easy cleaning … Continued

This compact and powerful circular connector boasts high power transmission, compact design, large temperature range and convincing electro-mechanical features. Perfect for many applications in automation, robotics, packaging, manufacturing… the applications are endless! • Power transmission to 16 A and 630 V • Protection IP 67 and IP 69K • Cable diameter up to 11 mm … Continued

This new M12 Power circular connector opens the door to entirely new applications and capabilities. This compact and powerful circular connector boasts high power transmission, compact design, large temperature range and convincing electro-mechanical features. A major milestone in an age of miniaturization. • Power transmission to 16 A and 630 V • Protection IP 67 … Continued

A major milestone in an age of miniaturization we present the “NEW” M12 Power Connector! It boasts high power transmission, compact design, large temperature range and convincing electro-mechanical features. This compact and powerful circular connector meets demand for more power with a smaller footprint yet still has internationally proven quality and conforms to Global Norm … Continued

Sealcon will be attending the 2016 Offshore Technology Conference May 2-5. Please stop by Booth #6305 and say hello and learn about all the great products available. We have many products to showcase including our Exios Cable Glands that offer a certification of cCSAus, UL, Class 1; Div 1, Class 1; Div 2, Class 1; … Continued

The industrial Ethernet connector is becoming increasingly important in the world of automation technology. In this era of Industry 4.0, everything is about the reliability and speed of data transmission. M23 RJ45, M12, M16, M23 Hybird Read More about the one and 2 plug solutions available at Sealcon.

This is a great guide to help you choose the best EMI/RFI Connector solution View EMI/RFI Guide. If you have additional questions and would like to talk to one of our technical sales staff call 1800-456-9012. Click to shop all EMI/RFI Strain Relief Fittings

Ever wonder what all those Ratings and Approvals mean? Use this good guide to help explain some of those questions. Explanation Guide

M12 Power Connector Top performance in minimum space: The new M12 Power transmits up to a nominal voltage of 630V and a rated current of 16A. It is a major milestone in an age of miniaturisation: the presentation of the M12 Power connector for power transmission. HUMMEL AG will present this connector to the public … Continued

Take a couple steps back and think about the moment you first realized how easy it was to connect two LEGO pieces. Do you remember the “AH-HA” feeling you had once you grasped the simplicity of building towers and the endless possibilities you had uncovered? You’ll experience a similar feeling when you discover the process … Continued

As a society, it’s been our mission to find ways in which we can enjoy the best of both worlds. From chicken and waffles to labradoodles, we’ve become masters at having our cake and eating it too. Similarly, our Snapclic DUO offers two solutions in one: strain relief and conduit fitting. Not only are your … Continued

Stainless steel is to corrosion what lead is to kryptonite; just as lead blocks kryptonite radiation, stainless steel blocks corrosive damage. The difference? Lead is a heavy metal that occurs naturally in Earth’s crust, while stainless steel is produced by combining chromium, nickel, molybdenum, titanium, copper, carbon and nitrogen. There are many grades of stainless … Continued

Bureau of Export Administration? No, the U.S. Department of Commerce changed its name to Bureau of Industry and Security (BIS) in 2002. Maybe we’re talking flying out of the Bogalusa, LA airport for an upcoming show? Not quite. While Sealcon will be traveling to attend the 2015 Offshore Technology Conference, that show takes place in Houston, TX. … Continued

Our FP and RG Glands “may be safely used in producing, manufacturing, packing, processing, preparing, treating, packaging, transporting, or holding food” (FDA, 21CFR177.2600, 2014). These wash down strain relief fittings are made of 316L Stainless Steel and Silicone Seals and designed specifically for the Hygienic Industry. The smooth outer surface eliminates nooks and crannies which … Continued

The Exios MZ cable glands are designed for Armored Cables in Hazardous Areas. The Unique MZ Clamp Solution is designed to prevent braid or armor from sheering off under excessive cable torque. The EXIOS MZ cable gland is made from high-end raw brass and meets all of the latest ATEX / IECEx & CSA standards. The Exios … Continued

Complete TWILOCK Product Listing Twilock Features: • Clearly defined positioning • Can be locked with a slight roataion from OPEN to CLOSE • Multi-functional: Special thread allows use of Twilock and screw connection • Quick connecting with patented Polygon Lock • Easy handling, exceptional functionality • Resistant to vibration

Industrial Enclosure; Cover screws, assembly screws and plugs are included. https://www.sealconusa.com/cat/industrial-enclosure/ Features: Manufactured from high-performance Thermoplastic, Polycarbonate or ABS. These Enclosures are suitable for demanding OEM applications, e.g. for the protection of electronic and pneumatic components. Characteristics of ABS • Cost-effective • Light weight • Good chemical resistance • Easy to machine using standard tools … Continued

Sealcon has a large variety of Fiber-reinforced Polyester Enclosures • Feature plain walls and captive stainless steel screws for the cover • Suitable for chemical and petro-chemical environments • Sizes: Small, Medium and Large Due to their rugged construction, excellent corrosion and chemical resistance these enclosures are suitable for chemical and petro-chemical environments.

• Approvals: CE, UL, CSA, German Lloyd, RoHS, Deca BDE • Our Enclosures are manufactured using the highest grade Thermoplastics, PC (Polycarbonate), designed for demanding OEM applications (e.g. protecting electronic & pneumatic components). PC Enclosures are UL Approved. This series with plain sidewalls is also available with Flange and Metric Knockouts. A special feature is … Continued

EXIOS – Cable Glands for Use in Hazardous Locations High-end Cable Glands for armored cables in hazardous areas including the latest IECEx and ATEX certifications, for use in Ex-e, Ex-d and Ex-tD areas • Dual seal on inner and outer jacket of the cable

High-end Cable Glands for armored cables in hazardous areas including the latest IECEx and ATEX certifications, for use in Ex-e, Ex-d and Ex-tD areas • Innovative “Interlocking Armor Cone” • Zero torsion on cable cores and armor • Fast and easy pre-assembly by hand by the use of profile material with maximum grip

Cable Glands for Use in Hazardous Locations or Explosion Proof Areas Sealcon is now carrying a new Hummel Strain Relief, Cable Gland, Cord Grip built for the Hazardous Locations According to the latest IECEx and ATEX standards Ex-d / Ex-e Zone 1, Zone 2, Zone 20, Zone 21 und Zone 22 Gas Groups IIA, IIB … Continued

PG to PG Threads or Metric to Metric Thread Is your thread size off by one size? Well, then these Stainless Steel Reducers will solve that threading problem. They convert holes which fit PG / Metric threads to a smaller female thread of the same thread type. Materials: • Stainless Steel • Optional O-Ring: Buna-N, … Continued

NPT to PG Threads & NPT to Metric Threads These NPT Adapters were made especially to help solve the conversion from NPT to either PG and Metric. Fits knock-out in box. Converts hole which fits NPT threads to a female PG or Metric threaded hub. Materials: • Nickel Plated Brass • Optional O-Ring: Buna-N, Viton® … Continued

Hub Kits include NPT adapter and nut. Fits knock-out in box. Converts hole which fits PG / Metric threads to a female NPT threaded hub. PG to NPT Threads, Metric to NPT Threads. Dealing with foreign products? Is connecting a challenge? Adapters will allow you to switch between PG, NPT & Metric threads to fit … Continued

With this solution you get the best of both worlds. • Combination of Strain Relief and Conduit Fitting • Push-in system • Partially rotatable • Can be equipped with Multi-Hole inserts • Metal style can be changed to EMI/RFI Pressure Rating: IP 68 (10 bar) rated at the installation side, IP 54 on the Conduit … Continued

PG 7, PG 9, PG 11, PG 16, PG 21, PG 29, PG 36, PG 48 These Turn-to-seal fittings fit the same conduit as SM Push-in fittings. They offer an economical solution for machine builders. The elbow has a smooth inside transition, making installation of cable and wires easy. Features: ST & ET Fittings are … Continued

This STANDARD corrugated conduit is made of flame retardant & UV resistant Nylon. Most universal UR Listed for cable protection conduit for medium to high mechanical stresses. High angled consistency fixed and moderate flexing installations. This Standard Corrugated Conduit is made of flame retardant Nylon. This Conduit is suitable for static and moderate dynamic installations. … Continued

https://www.sealconusa.com/cat/circular-connectors/m23-rj45/ Sealcon / Hummel offer the best heavy duty connector solution, We offer everything from straight female or male, Panel Mount, Single Hole Mount, Elbow Connector when it comes to a RJ45 solution.

Inserts & Configurations: 6, 7, 9, 12, 16, 17 & 19 Pole Contact: 1 mm, 1.5 mm & 2 mm Machined Lengths Features: • Fewer parts • One step cable assembly with optional EMI shielding • No tools required to insert and extract contacts • Crimp contacts machined or on tape • Solder contacts for … Continued

Stainless Steel Connectors can be used in many applications, where the environment dedicates a corrosion proof solution. M23 Signal Connector Features: Fewer parts; One step cable assembly with optional EMI shielding; No tools required to insert and extract contacts; Crimp contacts machined or on tape; Solder contacts for manual soldering or dip soldering for PC … Continued

Ideal for AC/DC motors & to convert from existing M23 applications. Fits Cable Diameters: .08 – .43″ (2 – 11 mm) Available Flange Sizes: 20 x 20 mm & 25 x 25 mm

SEALCON carries a large assortment of Hummel Cable Management Components consisting of Liquid Tight Cord Grips, Circular Connectors (M16, M23, M27, M40, RJ45, Profinet & Twintus), Industrial Enclosures (Plastic & Metal). Types: Dome, Flex, Elbow, EMI/RFI, Clamping, X-Large, Mini, PVDF, Stainless Steel, Zinc, etc. Threads: NPT, Metric & PG. Industries Served: Rotary and Linear Encoders, … Continued

Strain Relief, Cord Grips, Cable Glands https://www.sealconusa.com//cat/cable-gland-strain-relief/pvdf/ For Extreme Temperature Applications And The Chemical Industry, These fittings have outstanding chemical resistance and can tolerate, without problem, high and low temperatures. Use with nylon or nickel plated brass nuts. These Fittings have outstanding chemical resistance and can tolerate high and low temperatures. Use Nickel Plated Brass … Continued

For Harsh Environments & Extreme Temperature Applications These fittings have outstanding chemical resistance and can tolerate, without problem, high and low temperatures. Use with nylon or nickel plated brass nuts. UL, CSA, UR, CE, RoHS & Deca BDE approved. Also avilable in EEx e or ATEX versions. When it comes to solving problems Sealcon is … Continued

https://www.sealconusa.com/ncemi-selection.html These Liquid Tight EMI / RFI – Proof Grounded Strain Relief Fittings made of nickel plated brass are the perfect answer to stringent requirements for reliable grounding and protection from electromagnetic interference (EMI). The STANDARD version has an integral O-ring, which presses the braiding against the inside wall of the body but can only … Continued